此帖出自RF/无线论坛

最新回复 | ||

|

个人签名

射频【放大器】 |

||

|

|

|

此帖出自RF/无线论坛

| |||

|

个人签名

射频【放大器】 |

|||

|

| |

|

个人签名

射频【放大器】 |

|

浏览过的版块 |

- 有奖直播报名中!抢占工业4.1先机,WT·世健科技日等你来!

- 罗姆有奖直播 | 重点解析双极型晶体管的实用选型方法和使用方法

- STM32N6终于要发布了,ST首款带有NPU的MCU到底怎么样,欢迎小伙们来STM32全球线上峰会寻找答案!

- 免费下载 | 安森美电动汽车充电白皮书,看碳化硅如何缓解“里程焦虑”!

- 是德科技有奖直播 | 应对未来高速算力芯片的设计与测试挑战

- TI 有奖直播 | 使用基于 Arm 的 AM6xA 处理器设计智能化楼宇

- 安世半导体理想二极管与负载开关,保障物联网应用的稳健高效运行

- 报名直播赢【双肩包、京东卡、水杯】| 高可靠性IGBT的新选择——安世半导体650V IGBT

- 100W快充移动电源(0.91'OLED屏)

- 使用 MIC4575-3.3、6V - 24V 至 3.3V/1A 降压转换器的典型应用电路

- 【ART-Pi】多轮全向移动平台控制板

- 使用 Analog Devices 的 LTC1728HS5-5 的参考设计

- LTC2992CMS 双向宽范围功率监视器的典型应用

- 使用 NXP Semiconductors 的 MC9RS08KA2CPC 的参考设计

- 使用 Analog Devices 的 LTC1143LCS 的参考设计

- LT1086CT-3.6 具有自动光控制功能的低压差正稳压器的典型应用

- LTC2320IUKG-12 八进制、12 位 + 符号、1.5Msps/Ch 同时采样 ADC 的典型应用

- AD7854L 3V 至 5V 单电源、200 ksps、12 位采样 ADC 的典型低功耗电路

-

大家去逛慕尼黑上海电子展了不??

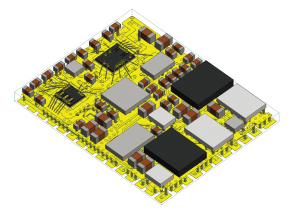

慕尼黑上海电子展于昨天开始了~~咱们的坛友们去逛展了不??有的话快来分享点前方碟照呀~~~正在逛展和有计划今明去逛的小伙伴,可以逛到Qorvo展台(展台号E44500)去看看,今年他们家展台上的看点还是挺多的~有多款全新的高集成度L-PAMiD解决方案、WIFI7方案 ...

-

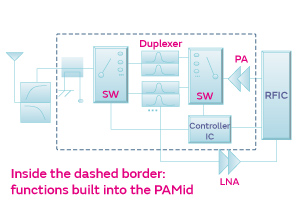

5G 射频前端的终局之战:毫米波

在上周于苏州举办的射频设计与测试论坛上,Qorvo公司高级销售经理赵玉龙发表了一个题为《5G射频前端的终局之战:毫米波》的演讲。他首先指出,在最近几年,随着5G的到来,整个射频前端产业获得了飞速的发展,产品形态也从离散的器件,发展到模组化,并随之出 ...

-

【Follow me第二季第3期】 开箱 + RA6M5

简介等待了这么久,快递终于是到了,这块板子被里三层外三层的包裹着。箱子非常大,到最后只拆剩下了一点点。[attach]863648[/attach]板子正面照[attach]863649[/attach]板子附送的线[attach]863650[/attach]这个板子是我所有带网口的板子中唯一一个附送了网 ...

- EEWORLD大学堂----财哥说钛丝

- KiCad8怎么画异形焊盘?

- 好书共享-《实例解读51单片机完全学习与应用》

- 为什么EVC下加入ON_WM_NCHITTEST编译有错

- 【GD32E231_DIY】-01:原理图&PCB

- 请问2410LCD屏颜色不对的问题

- 给华硕超极本UX32LN升级屏幕

EEWorld Datasheet 技术支持

-

消息称铠侠最快明天获上市批准,市值有望达 7500 亿日元

11 月 21 日消息,路透社报道称,在贝恩资本的支持下,铠侠将于当地时间周五(11 月 22 日)获东京证券交易所上市批准。 根据其 IPO 指示价,铠侠的市值预计达到约 7500 亿日元(当前约

-

美国政府敲定对格芯 15 亿美元《CHIPS》法案补贴,支持后者提升在美产能

11 月 21 日消息,美国商务部当地时间昨日正式宣布将向格芯 GlobalFoundries 提供合计 15 亿美元(当前约 108.71 亿元人民币)的《CHIPS》法案直接资金,具体补贴发放将

-

SK 海力士宣布量产全球最高的 321 层 1Tb TLC 4D NAND 闪存,计划 2025 上半年对外出货

11 月 21 日消息,SK 海力士刚刚宣布开始量产全球最高的 321 层 1Tb(太比特,与 TB 太字节不同)TLC(Triple Level Cell)4D NAND 闪存。 据介绍,此 32

- UWB上车新花样,无线BMS也能用它?

- 填补国内空白!中国移动、华为等联合发布首颗GSE DPU芯片

- 三星电子 NRD-K 半导体研发综合体进机,将导入 ASML High NA EUV 光刻设备

- 苹果揭秘自研芯片成功原因:竞争对手没法用最新尖端技术

- 芯片大混战将启:高通、联发科涉足笔记本,AMD 被曝入局手机

- Exynos 2600 芯片成关键,消息称三星将打响 2nm 芯片反击战

- 曾称华为不可能追上!台积电制程遥遥领先,2nm未量产已招大客户抢单

- STM32和无源蜂鸣器播放声音的问题

- 车规级AECQ200介绍,混合铝电解电容器的选择

- 嵌入式教程_DSP技术_DSP实验箱操作教程:2-28 搭建轻量级WEB服务器实验

- OPA847IDBVR运放器国产替代

- AG32VF407测试UART

- 【得捷电子Follow Me第二期】第一章 收到货物的分享

- 请问这个红外接收头是什么型号?能用哪个型号代替?谢谢

- 出售全新未拆封ZYNQ 7Z020 FPGA核心板

- 用在锂电池供电的水表设置上的LORA模块,当有100块水表集中安装在一个楼道内时,节能

- 请问一下,当某个端口被设置为 RX0后,这个端口的输入输出方向还有必要设置吗

- 今年怎么这么难,比疫情时还难,三十了面临失业好迷茫

- 请教稳压管测试问题

- 【小华HC32F448测评】关于小华半导体的UART中断发送和PRINTF构造和重定向

- 【BIGTREETECH PI开发板】 HDMI输出测试

- 【BIGTREETECH PI开发板】+08.音频测试(zmj)

提升卡

提升卡 变色卡

变色卡 千斤顶

千斤顶